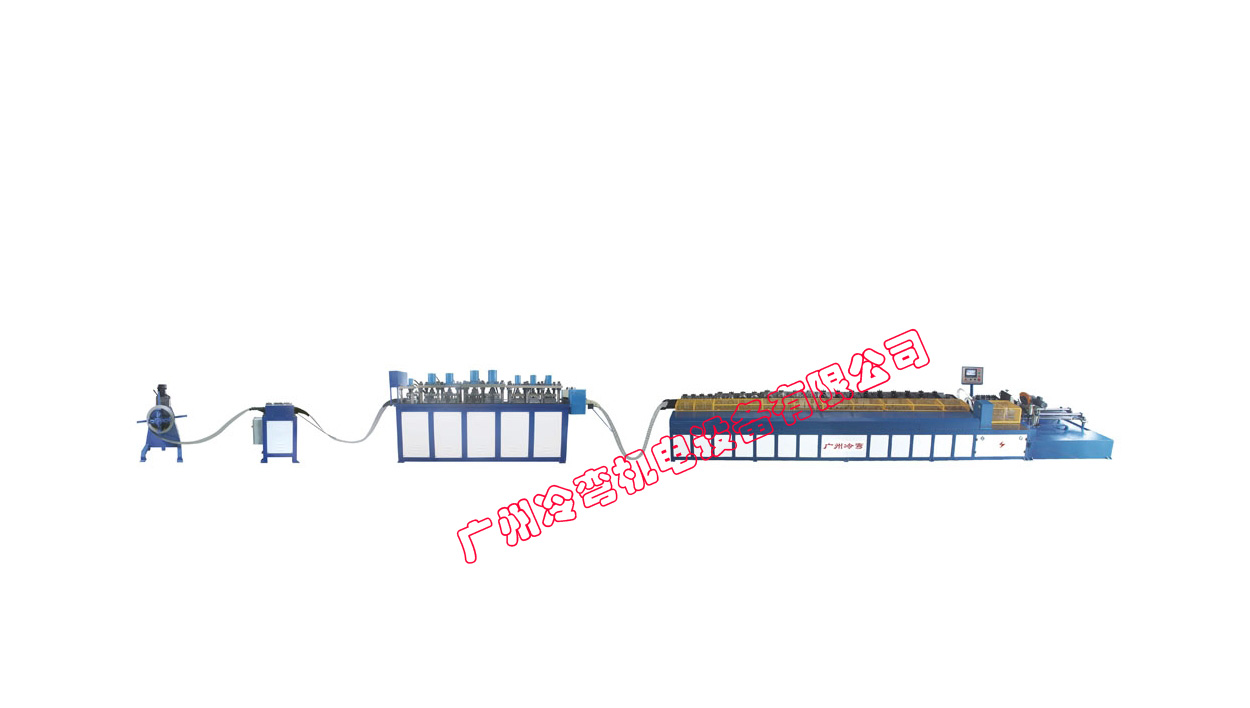

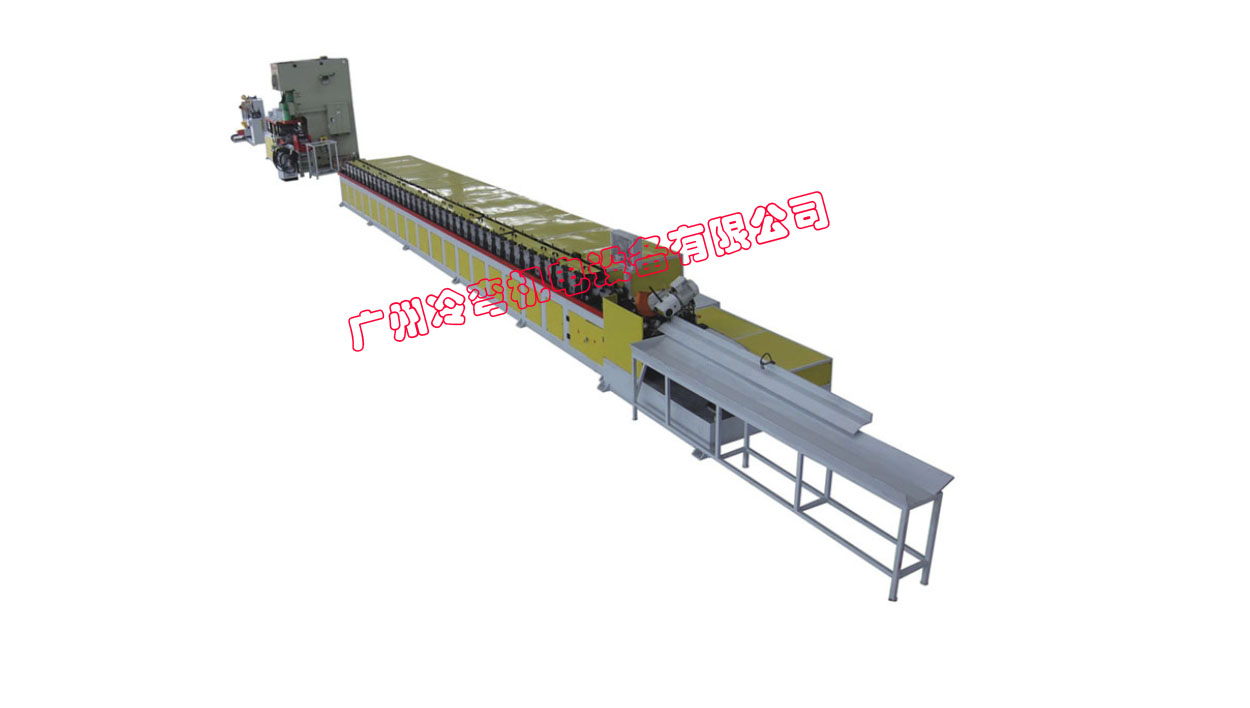

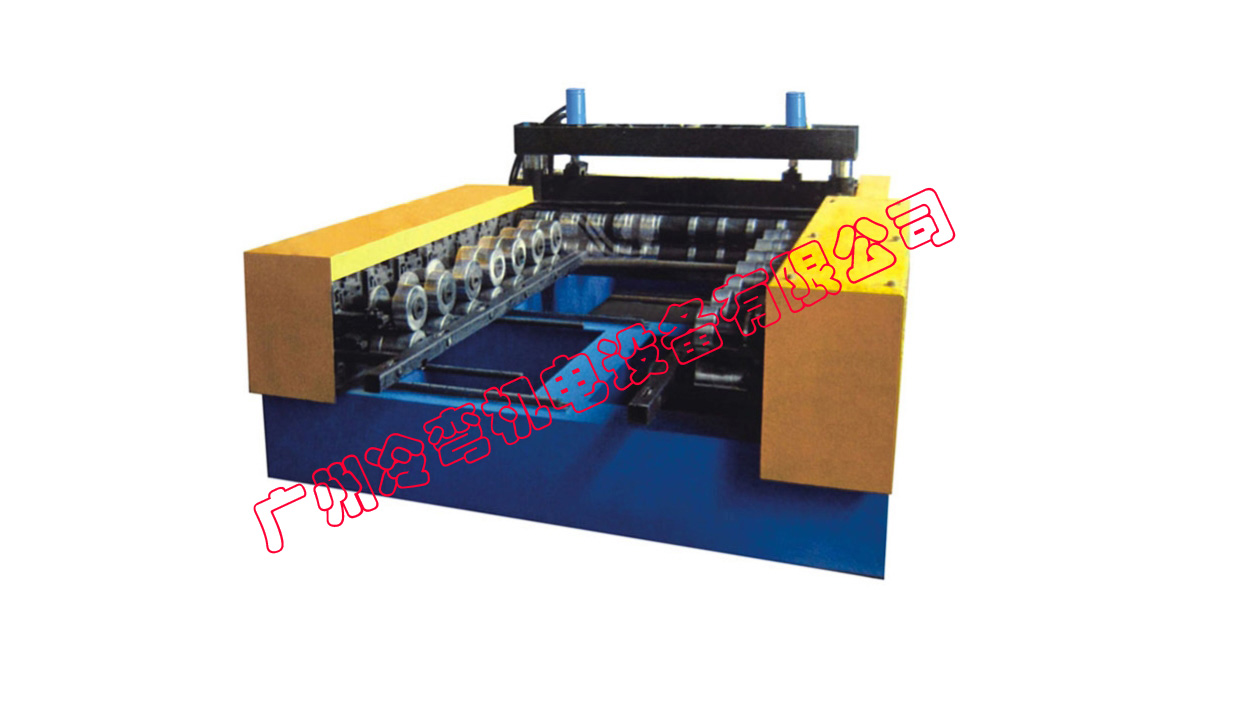

The advanced assembly line technology, full automatic control. USES the advanced servo feed, Germany's Siemens PLC control, variable frequency speed regulation, the man-machine interactive interface, change the product specifications, setting parameters is very convenient and quick. With more independent set of punching die, hole distribution and laws of change can be adjusted as needed, the number of the products before entering the molding all good and shear part adopts advanced servo flying shear control system, and don't stop cutting precision, widely used in cable tray, electric tank columns, doors, etc., realized the high, fast and fine mass production.