广州冷弯机电设备有限公司

Guangzhou Cold Roll-forming Mechanical & Electrical Equipment Co.,Ltd

Guangzhou Cold Roll-forming Mechanical & Electrical Equipment Co.,Ltd

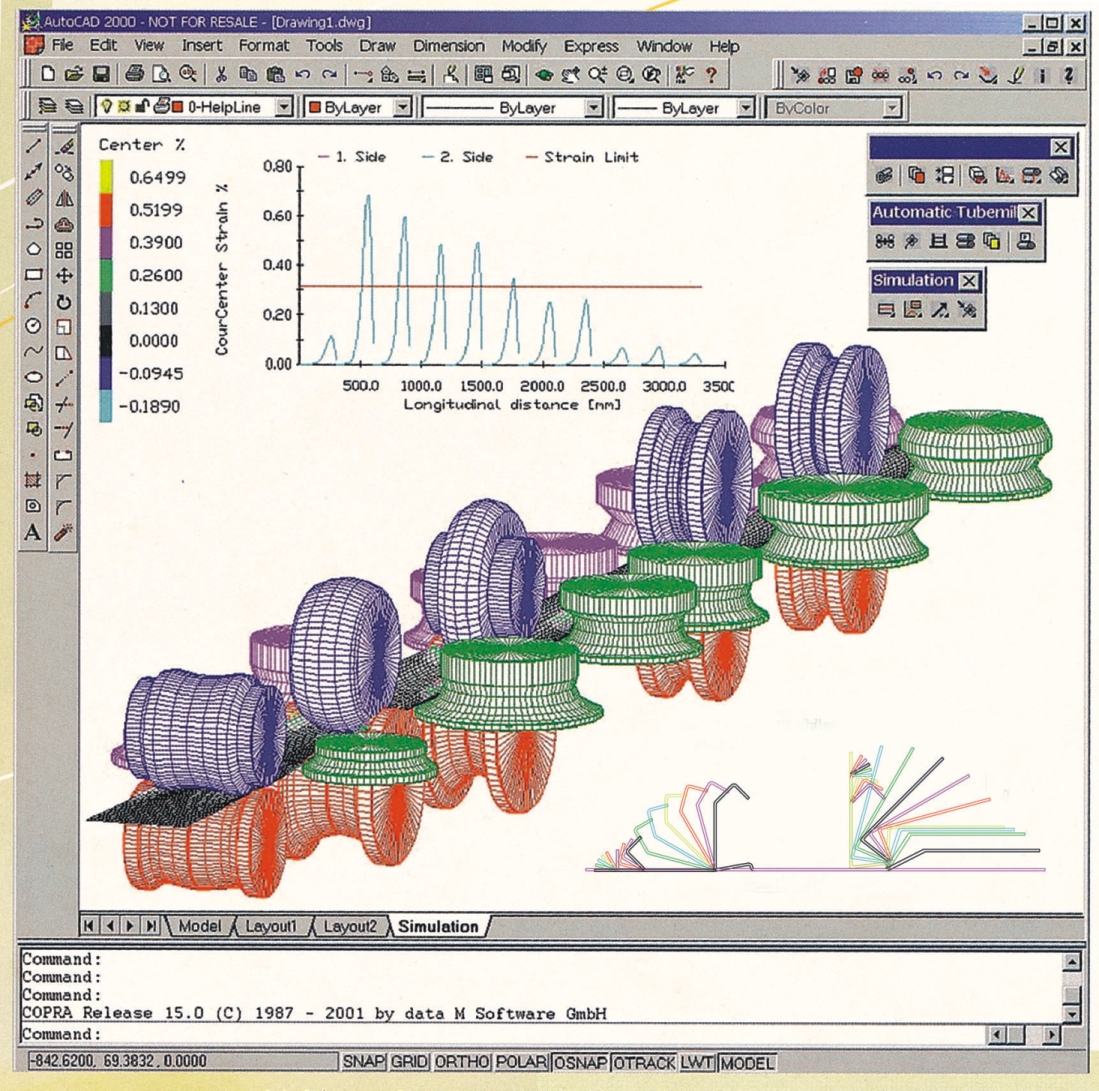

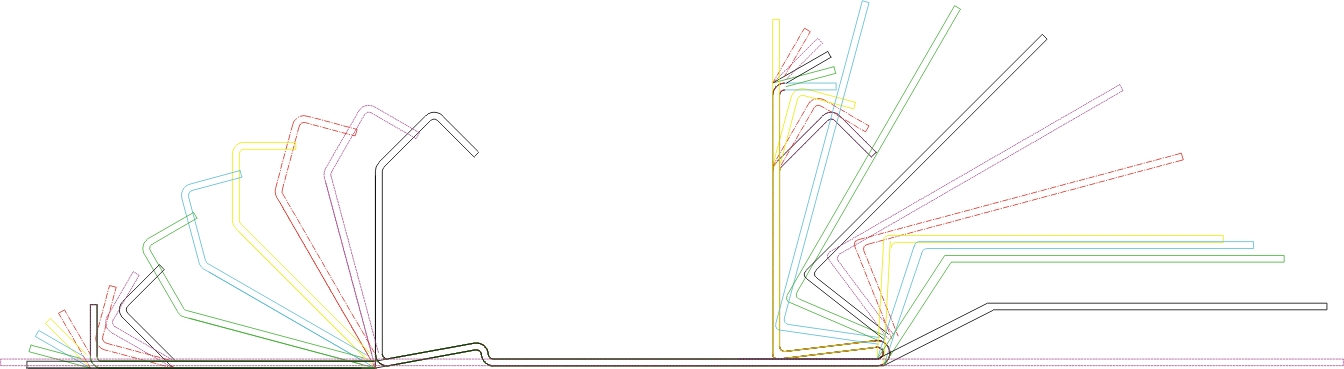

Design for cold roll forming roller During the whole process from design, calculating and simulating of forming techniques of the roller figures in the beginning stage, to the roughcast management computer digital controllor manufacture and quality control, we provide all the solutions through CAD/CAM,and by optimizing the product qulity. minimizing the time needed in the project, overcome the residual stesss and the costs for replacing and installing the new roller, etc in the cold roll-forming process.The product quality has fulfilld the requirements in GB6723-86" imensions, requirements, weight and discrepancy allowed for the general profile steel with cold roll-forming opening "and the GB6725-86" Technical condtions for cold roll-forming profie steel".

Cold rllforming profile steel is a kind of the economic section steel material with theextensive applications, and has been widely applied in various sectors and industries such as construction, transportation, machinery and electric home appliance,etc. The profile steels have the reasonable section structures,diverse categories and specifications and accurate geometric dimensions,and have reflected the use requirements for the light-weight reasonable and functional materials in the modern society., For the convenience for selection and use by customer, our factory adopts the method of roughcast categorization to name the cold roll-forming machines,So as to be convenient to compare the technical & economic parameters of the machine groups.

——————————— Forming Rollers ——————————

● We own the fastest rolling-pressing molding flow line in China with the speed at 50m/min,and the cutting speed for 30m/min.

● In cooperation with Rexroth in Germany, we have developed the high-speedfly cutting system.

● We are capable to produce the hardware products reputed as no tolerance for Germany.

Roll Forming Automatic High-speed Punch Line