广州冷弯机电设备有限公司

Guangzhou Cold Roll-forming Mechanical & Electrical Equipment Co.,Ltd

Guangzhou Cold Roll-forming Mechanical & Electrical Equipment Co.,Ltd

Roof tile equipment is made up of feeding stand, molding machine, hydraulic cutting, carrier aircraft parts. According to all kinds of double caigang watts, glazed tile, wall panels, roof tile standards and requirements of custom-made special equipment, the whole production line fully automatic control.

Technical Data:

|

Molding material |

Number of Forming |

Production speed |

Cut off the way |

Production quality |

Run environment |

|

0.25 ~ 0.8mm manufacture, galvanized sheet, stainless steel |

About 12 ~ 20 stands |

8~15m/min |

Hydraulic cutting |

No fold, uneven surface, such as scratch defect Product section size and hole size meet the requirements of customers drawings or national standard |

380V±10% / 50Hz |

|

Molding Material |

0.25~0.8mm manufacture, galvanized sheet, stainless steel |

|

Number of Forming |

About 12 ~ 20 stands |

|

Production speed |

8~15m/min |

|

Cut off the way |

Hydraulic cutting |

|

Production quality |

No fold, uneven surface, such as scratch defect Product section

size and hole size meet the requirements of customers drawings or national standard |

|

Run environment |

380V±10% / 50Hz / 15KW |

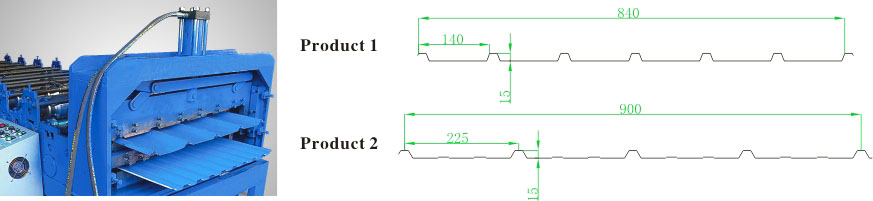

Type 840/900 double - layer tile press

Roll Forming Automatic High-speed Punch Line